Overview of a Ships Steam System Auxiliary system

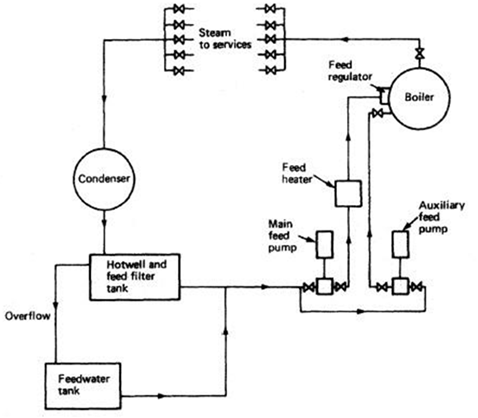

As the names imply, the exhaust gas economizer is a waste heat recovery system that recovers heat from exhaust of main or auxiliary engines and thus generally does not use fuel. The more the second system is used, the less will be a need for use of the auxiliary boilers, thus good maintenance and operating conditions of exhaust gas economizer should always be regarded as part of energy saving in the steam system. Figure 28 below shows a typical steam system for a ship.

Figure 28: A typical auxiliary boiler steam system configuration (MariEMS 2017).

For the sake of presenting the energy efficiency case, the ship-board steam system will be divided into the following parts:

The auxiliary boilers: This is where the steam is produced using fuel.

The exhaust gas economiser: This is where the steam is produced via waste heat recovery of the exhaust gases.

- The steam distribution system: This refers to steam piping system and relevant instruments and devices used for steam controls.

- Steam end-use: This refers to all the steam consuming systems such as steam turbines, freshwater generators, steam heaters, etc. (MariEMS 2017).

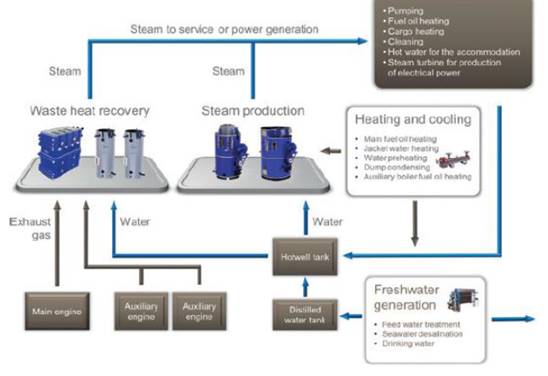

Figure 29 below shows a typical arrangement for such components.

Figure 29: Overall ship-board steam system (MariEMS 2017).