Engine Load Management

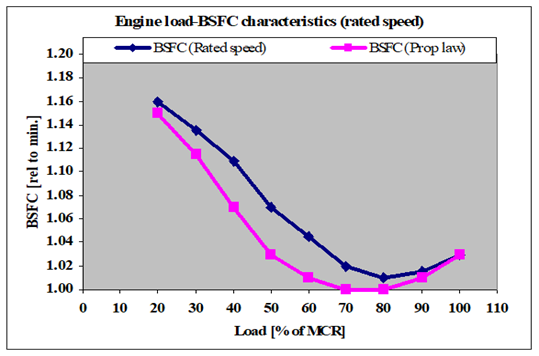

It is well known that the efficiency of a diesel engine is a function of its load level or its load factor. Figure below shows the engine Specific Fuel Consumption (SFC) as a function of the load factor.

Figure 22: Engine SFC as a function of load factor (MariEMS 2017).

Load factor: The engine load factor is defined as the actual power output of the engine relative to its Maximum Continuous Rating (MCR). The Load factor is normally specified in percent. An engine working at 50% of its maximum load has a load factor equal to 50%.

In figure 22 above, the curve for constant engine speed operation (rated speed) represents operation of electric generation engines (such as auxiliary engines, e.g. diesel generators) and the curve for propeller law shows the main engine operation characteristics. As can be seen there is no significant difference and for both types of application, the engine’s SFC (Specific Fuel Consumption g/kWh) varies with the engine load. SFC is a minimum (i.e. efficiency is a maximum) for a certain load level; typically for engines it is in the range of 70 to 90% of an engine’s Maximum Continuous Rating (MCR). The above diagram also shows that under low load conditions, the SFC of the engine will increase (engine efficiency will reduce). Although the load on the main engine is primarily dictated by ship speed, the load on the auxiliary engines depends on the ship-board electrical loads that are a function of the number of machines, machinery and equipment being used at each point in time plus the number of engines used to satisfy the requirements. In this Section, it is argued that engine loads should be managed, where possible, so that the engine fuel consumption is minimised. This will effectively mean operating the engines at 70 to 90% load range as discusses above with reference to figure 22 above. The lower consumption of fuel by each kW per hour output by the engine is when this, is running with a load between 70-90% (Mari+EMS 2017).