Ship-Level Energy Management Plan (SEEMP)

EEMs at the core of a SEEMP:

In this section, ship-level energy management is discussed with specific reference to SEEMP. The methodology for the development of a SEEMP should be based on the IMO MEPC guidelines. Accordingly, the SEEMP development involves all aspects of planning including:

- Identification of current status of the ship in terms of energy use and performance.

- Target setting for energy use or energy performance of the ship (voluntary).

- Identification of EEMs (Energy Efficiency Measures).

For each selected EEM for implementation, the following should be done:

- Definition of implementation method,

- Definition of monitoring method

- Definition of assessment method

- Documentation of all the above in the SEEMP.

Under IMO SEEMP development guidelines, there is no requirement for the development of an “energy policy” and setting target for energy saving is also voluntary (MariEMS 2017).

Implementation of EEMs: The implementation of a SEEMP could take a variety of forms. It is argued here that each of the EEMs within a SEEMP needs to be implemented as if it is a form of a “technical and operational project”. The term project is used here to emphasise that each EEM need to have a starting date and end date, it would have a budget and responsible person(s), it would have criteria for monitoring and measuring success and so on. As far as a shipping company’s energy management activities are concerned, the ship-board activities are mostly devoted to the implementation side. This means that various identified EEMs need to be implemented by ship staff (MariEMS 2017).

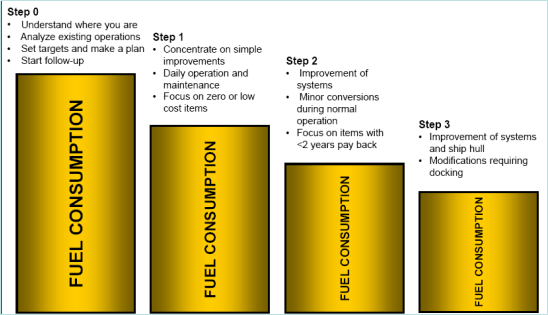

Continuous improvement approach: To include continuous improvement, the energy management systems will be done in steps through a number of cycles

Figure 17: Step by step approach to energy management (MariEMS 2017).

- Step 0 (initial planning): Understand where the ship/company is, analyse potential for improvements and decide where the ship/company wants to save energy and start defining the target and develop the energy management action plan.

- Step 1 (low cost measures): These are normally referred to EEMs that can be implemented at zero or very low cost. They are the so-called “low hanging fruits”. In this step, the concentration will be on these EEMs that may largely include aspects such as improvement to daily operations and maintenance activities.

- Step 2 (medium cost measures): When step 1 targets are achieved, then EEMs that would involve some cost expenditure for implementation will need to be handled.

- Step 3 (high cost measures): These are measures that may have significant cost of implementation (e.g. technology upgrade) or commercial implications (e.g. slow steaming or itinerary changes). These measures need significantly more analysis, deliberations with stakeholders (e.g. charterers) and so on. In fact, the longer-term potential for financial return for these measures may be higher compared to other measures but elements of risks are also higher (MariEMS 2017).