International Energy Management Standards

The international energy management standards can be summarised in two parts as outline below:

Part 1: ISO 50001 Energy Management System

The International Organization for Standardization (ISO) created ISO 50001 as a voluntary international standard for a ship's energy management in order to improve the energy performance. The standard addresses the following:

Energy use and consumption evaluation via conducting energy reviews and development of energy policies. Measurement, documentation and reporting of energy use and consumption.

Design and procurement practices for energy-using equipment, systems, and processes.

Development of an energy management plan and other factors affecting energy performance that can be monitored and influenced by the organization.

(Ziarati et al, MariFuture, Development Papers, 2018-2019)(See for instance the 35th Development Paper published in July 2019 - http://www.marifuture.org/Reports/Development-Papers/ADP_07_2019_MARIFUTURE.pdf.).

”ISO 50001 applies to all different types of companies and industry sector. It provides a framework for an “Energy Management System (EnMS)” through which each organization can set and pursue its own goals for improving energy performance. From the ISO 50001 perspective, an EnMS is a series of processes that enables an organization to use data and information to maintain and improve energy performance, while improving operational and energy efficiencies and reducing environmental impacts”. (IMO: Module 6. 2016, 16.)

Part 2: ISO 19030 and application of SEEMP for EEOI requirements

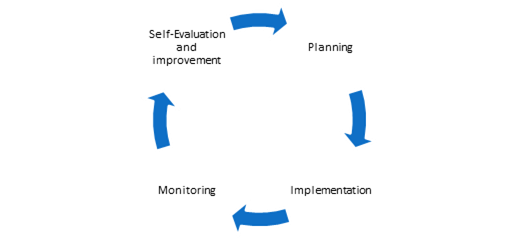

In comparison with other modes of transportation shipping is relatively efficient as far as the CO2 emissions, produced per mile, for each tonne of cargo is transported. Nonetheless, the IMO is researching at measures to improve ship efficiency through better management and implementation of best practice. The SEEMP is a ‘live’ document that will be ship specific, containing energy improvement measures identified by the ship owner which will be kept on board each ship. There are four key processes that the SEEMP addresses and describes and together they form a continuous improvement process as shown in Figure 7 below. (Ziarati et al, MariFuture, Development Papers, 2018-2019)

Figure 7: Four key processes (Ziarati et al, MaiFuture, Development Papers, 2018-19).

“The Ship Energy Efficiency Management Plan (SEEMP) is an operational measure to improve the energy efficiency of a ship in a cost-effective manner. The SEEMP also provides an approach to manage ship and fleet efficiency performance over time using, for example, the Energy Efficiency Operational Indicator (EEOI) as a monitoring tool”. (IMO www-pages, 2020.)

The ISO 19030 was developed for the assessment of the hull and propeller's performance for ships in service. Nowadays hull and propeller performance is a ship efficiency killer. The reasons for this inefficiency are a combination of ‘biofouling’ and mechanical damages. The reason for this is the inability to properly measure the damage.

ISO 19030 outlines general principles of, and defines both a default as well as alternative methods for, measurement of changes in hull and propeller performance. It shows the way to calculate a set of four performance indicators for hull and propeller related maintenance, repair and retrofit activities. Those are “In-service performance”, “Dry docking performance”, “Maintenance trigger” and “Maintenance effect”. (Ziarati et al, MariFuture, Development Papers, 2018-2019).